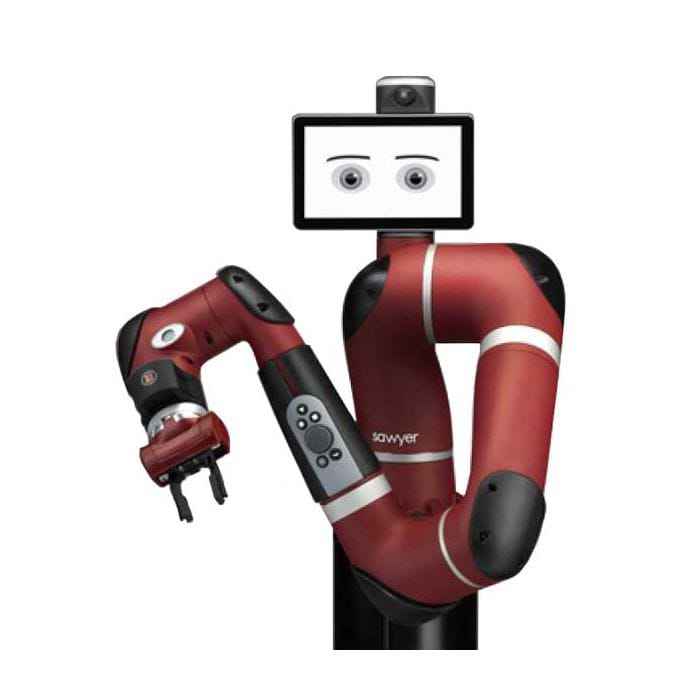

Sawyer Robot

Sawyer is the revolutionary collaborative robot designed to execute tasks that have been impractical to automate with traditional industrial robots.

Sawyer gives manufacturers the high-performance automation they need, while maintaining the flexibility, safety and and ease of use.

Sawyer features a 7 degree of freedom robot arm with a 1260 mm reach that manoeuvers into tight spaces and operates in work cells designed for humans. Built-in force sensing capabilities allow it to make adaptive decisions as tasks run, enabling Sawyer to work precisely, while operating safely next to people. With his friendly design Sawyer is highly accepted by his human co-workers, which accelerates the introduction of automated solutions.

Software Driven Hardware: Easy application

Sawyer uses Rethink Robotics' flagship software, Intera.

The Intera software - that is continually updated and delivers production metrics in real-time. The combination of hardware and software, together with the ClickSmart gripper technology, allows Sawyer to be deployed faster and easier in more tasks and applications, and without time-consuming customization.

The robot can be trained by simply demonstrating the procedure moving its arm. The robot is up and running to perform a task within a matter of minutes and easy to use. That’s the Rethink difference – Intera makes Sawyer fast and easy to deploy.

Embedded and External Vision: Flexibility

Sawyer comes with an embedded Cognex Vision System in its arm that enables the Robot Positioning System (RPS) to provide for a dynamic reorientation and easy redeployment of the robot. With it´s 7 degrees of freedom and a 1260 mm reach, Sawyer fits into a variety of work cells – even ones already designed for people.

It can manoeuver into tight spaces, and around fixtures and doors, much like a human arm. The combination with the easy to use software enables a wide variety of applications without requiring additional hardware, software, or integration. That’s the Rethink difference – Intera makes Sawyer flexible to use.

High Resolution Force Control: Highly accepted by employees

While traditional industrial robots have to be kept behind cages, Sawyer is inherently safe, designed to work alongside people, and certified that it meets ISO requirements by TÜV Rheinland (ISO 10218-1:2011 and PLd Cat. 3). The safetyness in combination with his friendly eyes makes Sawyer not only higly accepted but also popular among employees.

Thanks to sensitive torque sensors embedded into every joint, Sawyer’s built in force-sensing allows constant force control where delicate part insertion is critical, or to use force feedback in tasks where verification of properly seated parts is needed. By controlling both force and position, Saywer controls the amount of force it applies to different directions, the same way people do when performing tasks, eliminating the need for additional sensors or hardware.

Technical Specifications:

- Weight: 19 kg (42 lbs)

- Payload: 4 kg (8.8 lbs)

- Repeatability 0.1 mm

- Max Reach: 1260 mm

- Typical Tool Speed: 1.5 m/s

- Degrees of freedom: 7

- Operating Temperature: 5° C - 40° C, 80 % relative humidity

- Joint Ranges: J0 - J3 = 350 degrees, J4 - J5 = 340 degrees, J6 = 540 degrees

- Power Requirements: 100-240 VAG, 47-63 Hz, 4A Max

- I/0 Ports (Controller): 8 digital in / 8 digital out

- Communication: Modbus TCP, TCP/IP

- IP Class: 54

- Collaborative Standards: ISO 10218-1 :2011

- I/0 End of Arm: 4 digital in / 2 digital out / 2 analog in /24 V DC 2A, ClickSmart plate required

- Actuation: Series elastic actuator and Harmonic Drive, with optical encoder

- Force sensing: High-resolution force sensing embedded at each joint

- Vision: Camera in the head for wide field of view and Cognex camera with built-in light source in the wrist for precision vision applications

- Software: Intera, with regular software updates

- Body: Sealed against dust and spray

- Expected lifetime: 35,000 hours (5 years)

- Certification: International ApprovalsBasic Specifications