TReX Dual Motor Controller DMC01

The TReX blends RC, analog, and serial inputs for a powerful motor control solution capable of delivering a continuous 13 A per motor.

The TReX will work right out of the box as an electronic speed control (ESC), but its ability to seamlessly transition between RC/analog and serial control makes it capable of so much more!

The TReX Dual-Motor Controller is a versatile, high-power DC motor controller designed to seamlessly blend autonomous and human control of small- and medium-sized robots. The TReX can control two bidirectional and one unidirectional motor via three independent control interfaces: radio control (RC) servo pulses, analog voltage, and asynchronous serial (RS-232 or TTL). It maintains compactness through a two-board design that features the VNH2SP30-based Dual High-Current Motor Driver Carrier as its bottom layer. (For a lower-power version of the TReX, please consider the TReX Jr).

The TReX uses five input channels to receive the RC or analog control signals. When operating in RC or analog mode, the five channels function as follows:

- Channel 1: motor 1 speed and direction or, if in mix mode, turn left/right

- Channel 2: motor 2 speed and direction or, if in mix mode, go forward/reverse

- Channel 3: auxiliary (unidirectional) motor speed

- Channel 4: can be used to enable “flipped mode”, which allows invertable robots to be controlled as normal when they are inverted

- Channel 5: determines whether the motors are controlled by the channel inputs or the serial interface; this channel allows you to switch between autonomous and human control at will

The serial interface can switch instantly with one of the other two interfaces, allowing mixed autonomous and remote control. For example, a robot could be configured to run autonomously most of the time, but a human operator could override the autonomous function if the robot gets stuck or into a dangerous situation. If the serial mode is selected as the primary interface, high-resolution measurements of all five channel input signals (be they RC pulses or analog voltages) are made available to the autonomous robot controller, allowing for complex and unlimited mixing of operator control and sensor input. For example, the TReX would be a great motor controller for a remotely controlled balancing robot.

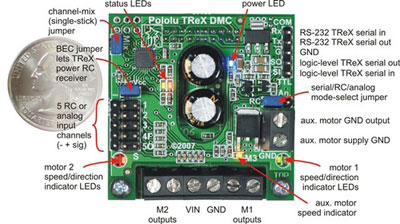

Pololu TReX Dual Motor Controller top view with LEDs, jumpers, and I/O labeled.

RC/Analog Control Features

- Battery Elimination Circuit (BEC) jumper lets the TReX optionally power your RC receiver or analog controller

- Mix-mode jumper allows for single-stick motor control of differential-drive robots

- Automatic calibration for your particular RC or analog controller (the TReX can learn the channel ranges)

Options accessable through the serial interface

- All five high-resolution channel input values are available

- Remapped channel input values show what the TReX would do if it were in control

- Optional 7-bit cyclic redundancy checking to ensure command/data validity

- Calibration values can be explicitly read and set

- Each channel can be reversed and parabolically scaled

- Current limit, acceleration, and maximum motor speed settings

- The bidirectional motors can (individually) be set to coast or variable brake when in the deadband

- Upgradable firmware

Safety features

- “safe-start” requirements prevent accidental motor activation at power-up

- Optional automatic motor shutdown on serial error, timeout, or input channel noise

Note: The TReX does not require use of the serial interface to function; it will work right out of the box as an electronic speed control (ESC). You will not have access to the full suite of features the TReX provides if you do not make use of the serial interface, though.

Servo cable accessories

The TReX has male 0.1" headers; for direct connection to an RC receiver or serial servo controller, we recommend ordering one 6" female-to-female cable, 12" female-to-female cable, or 24" female-to-female cable per channel you intend to use (the TReX can use up to five channels).

General specifications

Motor driver: VNH2SP30

Continuous output current per channel: 13 A

Continuous paralleled output current: 25 A

Technical specifications

| Dimensions | 1.9" x 1.9" x 0.8" |

| Supply voltage | 6 – 16 V |

| Primary motor outputs | 2 bidirectional, 30 A peak, up to 13 A continuous per channel (may be combined to control 1 bidirectional, 25 A continuous) |

| Auxiliary output | 1 unidirectional, 15 A continuous |

| Speed control | 128 steps in each direction |

| Control interfaces | RC servo pulses, analog voltages, or serial commands; master interface set by mode-select jumper |

| Input channels | 5 (RC servo pulses or analog voltages) |

| RC pulse measurements | 12-bit resolution, 1 us accuracy |

| Analog measurements | 10-bit resolution |

| Serial interface | both RS-232 and TTL (logic level), bidirectional |

| Baud rates | supports 11 common baud rates ranging from 1200 to 115,200 bps |

| Expanded protocol | Allows multiple Pololu servo and motor controllers on one serial line |

| Compact protocol | Allows both motors 1 and 2 to be simultaneously set with just three bytes |